One of the key enabling factors for steel decarbonization to happen at the needed pace is the availability of a sufficient supply of sustainable power. Indeed, as solutions emerge to rid the sector of its dependence on coal, their decarbonization potential is highly dependent on whether they still use fossil fuels or not. Yet major banks remain far from enabling the deep decarbonization of the steel sector: between 2021 and 2024, the world’s 65 largest banks channeled more than twice as much financing into fossil fuels as into sustainable power supply. By failing to support the development of sufficient sustainable power supply, banks are jeopardizing the decarbonization of the steel sector as a whole.

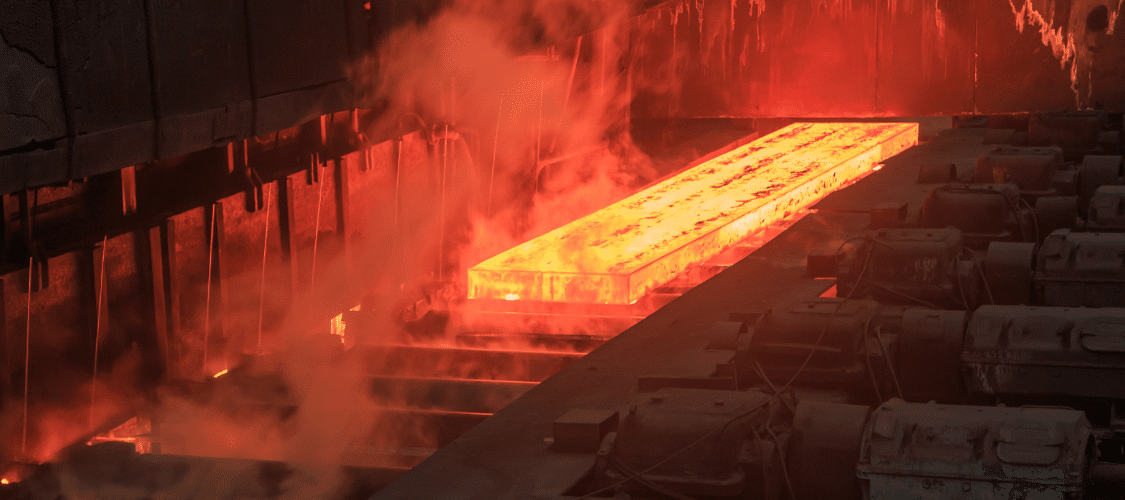

The steel sector is currently responsible for 11% of global CO2 emissions. (1) Decarbonizing it requires moving away from coal-based production, which represents 70% of total steel production. (2) Although the steel sector has long been considered ‘hard to abate,’ technological advances now make deep decarbonization achievable, with the potential for the industry to become coal-free as early as the 2040s. (3)

Steel production can only be as sustainable as the power it runs on

The steel sector’s best chance at decarbonizing rely on options that are highly electricity-intensive: (4)

- increasing the circularity by recycling more steel scraps, in electric arc furnaces (scrap-based EAFs); (5)

- directly reducing the iron with green hydrogen (green H2-DRI) – which requires substantial amounts of sustainable power to be produced – which can then be loaded into an electric arc furnace to produce steel (green H2-DRI-EAF). Currently, about 7% of total iron production is done through fossil gas-based DRI, which would then need to be retrofitted to use green hydrogen once available; (6)

- direct electrification through electrolysis, a promising technology but which is not yet scalable. (7)

The green hydrogen–DRI–EAF route for steelmaking is far more electricity-intensive than either the traditional BF–BOF process or the EAF route for recycling steel. (8) The IEA’s Net Zero by 2050 Scenario highlights the need to expand EAF and green H2-DRI capacity to meet decarbonization targets. (9) Achieving fossil-free steel therefore requires a major increase in sustainable electricity. Estimates suggest that just meeting 2021 steel production levels would need 97.6 Mt of hydrogen and 1,371 GW of renewable energy – nearly half of today’s global renewable capacity. (10) Overall, to meet rising steel demand, sustainable electricity demand for steel could grow 4.2-fold by 2050. (11) Closing this substantial capacity gap requires banks to shift finance from fossil fuels to sustainable power.

Banks must power steel decarbonization

The true potential and deployability of steel decarbonization technologies is challenged by the currently insufficient supply of sustainable power sources. (12) This is not due to a lack of demand, as green steel demand is rising much faster than what can be supplied, driven by demand-side sectors like automotives. (13) Higher costs should also not be seen as an obstacle: while a ‘green steel premium’ exists today, its significance is expected to decline by 2050. (14) This is in part due to falling costs of sustainable electricity, such as wind and solar, as well as falling costs for battery storage. (15)

This is why banks must increase their support to sustainable power. Yet, their action so far is highly insufficient: between 2021 and 2024, the world’s 65 largest banks financed fossil fuels more than twice as much as sustainable power — US$3,285 billion versus US$1,368 billion, a ratio of just 0.42:1, ie 42 cents went to sustainable power supply for each dollar going to fossil fuels. This falls short of the IEA’s NZE scenario ratio of 6:1 by 2030. Worryingly, these 65 banks have shown no sign of progress since 2021.

While European banks are slightly ahead when it comes to financing sustainable power, they are nowhere near what is needed, with a regional ratio of 0.7:1, which is highly insufficient to support the electrification of the European steel industry which has substantial CO2 reduction potential. (16) While this should be a priority for European banks to counter current challenges that the steel sector is facing in Europe, (17) banks like BNP, Crédit Agricole, and ING keep granting unconditional support to steelmakers going in the wrong direction: they have for instance participated in a USD650 million bond issued by ArcelorMittal on September 30, (18) despite the steelmaker constantly failing to deliver on its decarbonization promises in Europe. BNP and Crédit Agricole have also participated earlier in September in bond issuances from major met coal developer BHP, with maturity dates of six and ten years. Despite the adoption by these four banks of some policy restrictions on met coal developers and coal-based steel, these transactions clearly highlight the need to strengthen policies to have an actual impact.

Furthermore, many banks – especially in Europe – have adopted decarbonization targets for the steel sector. (19) Yet, they won’t be able to achieve them if they keep financing steelmakers and their met coal suppliers without restraint. In addition, they should also adopt robust sustainable energy financing targets to accelerate steel decarbonization.

Failure to act would lead the steel sector straight into the gas trap

One of the most promising steel decarbonization options is the use of green hydrogen to replace coal to produce the chemical reaction needed to liquify iron ore. Indeed, H2-DRI based steelmaking can save close to two tonnes of CO2 per tonne of steel compared to coal-based steelmaking. (20) Steel decarbonization is a priority use of green hydrogen as it presents higher savings than other uses of green hydrogen. (21)

In order for this to happen, massive investments in sustainable power sources need to happen. The IEA Net Zero scenario estimates that producing virgin iron in 2050 – the most CO₂-intensive step in steelmaking – will require 54 Mt of green hydrogen annually, demanding 2,700 TWh of renewable electricity, (22) equivalent to the EU’s current annual electricity demand. (23)

As long as green hydrogen is not available, iron ore can be reduced using fossil gas instead. For now, steelmakers need to expand the deployment of green hydrogen-ready facilities, which will initially use fossil gas but must be retrofitted to use green hydrogen as soon as possible. Taking too long to switch to green hydrogen leads to increased risks of fossil gas lock-in, as steel facilities would use fossil gas for longer than they should have to. Green hydrogen production must be strictly reserved for sectors like steel, which have little other options to decarbonize, unlike the power sector. Banks failing to invest in sufficient sustainable power capacity, which is needed to produce green hydrogen, is therefore jeopardizing steel decarbonization.

The steel sector is one of the best use cases for sustainable electricity, as it provides one of the largest CO2 reduction levers per unit of electricity. (24) Yet, banks, even in Europe, are failing to support the development of sustainable power at a pace that would enable fossil-free steel production by 2050. Furthermore, they are ignoring some key geographies by almost only financing projects in the OECD and China, (25) when sustainable power capacity is also needed in other key locations, like India, to produce fossil-free steel. (26) Banks must urgently align their support to the energy system with the needs of a net-zero trajectory, as it is a necessary first step to decarbonize essential industrial sectors.